|

|

Back to 1" Back to plane chisels |

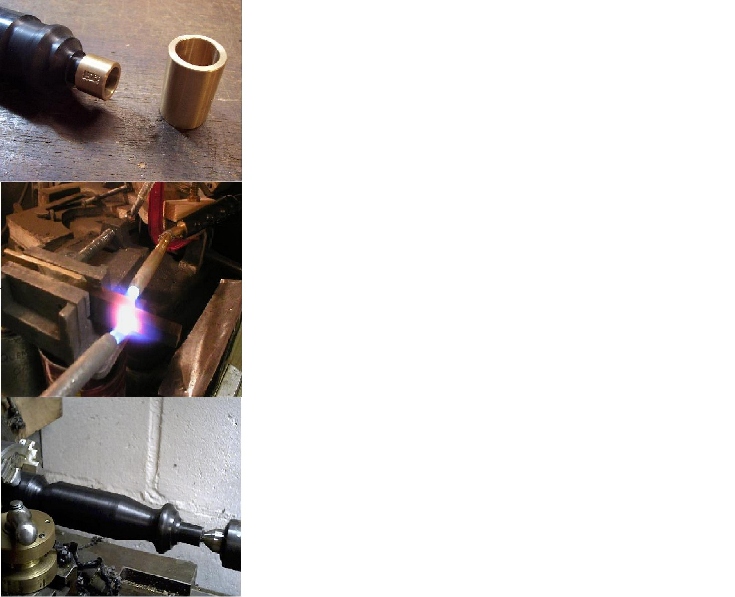

Chisel Making |

Each chisel is handcrafted. Turned by hand on a 150 year old lathe. The rock hard blades are cut and ground to shape from a solid piece of M2 steel. Then further flame treated for strength. Ferrules are turned from bronze stock, and will be the thickest, heaviest, you will find on a chisel. Approximately 1/8" wall thickness. They are then assembled, polished and lacquered. Sharpening is done with up to a 1200 water stone. Additional honing should be done after purchase, with at least the same grit or higher. The stock materials are very costly, and the production is so labor intensive, that prices have been raised a bit. Once you try the one inch, you will soon see why its all worth it !!! |